Support

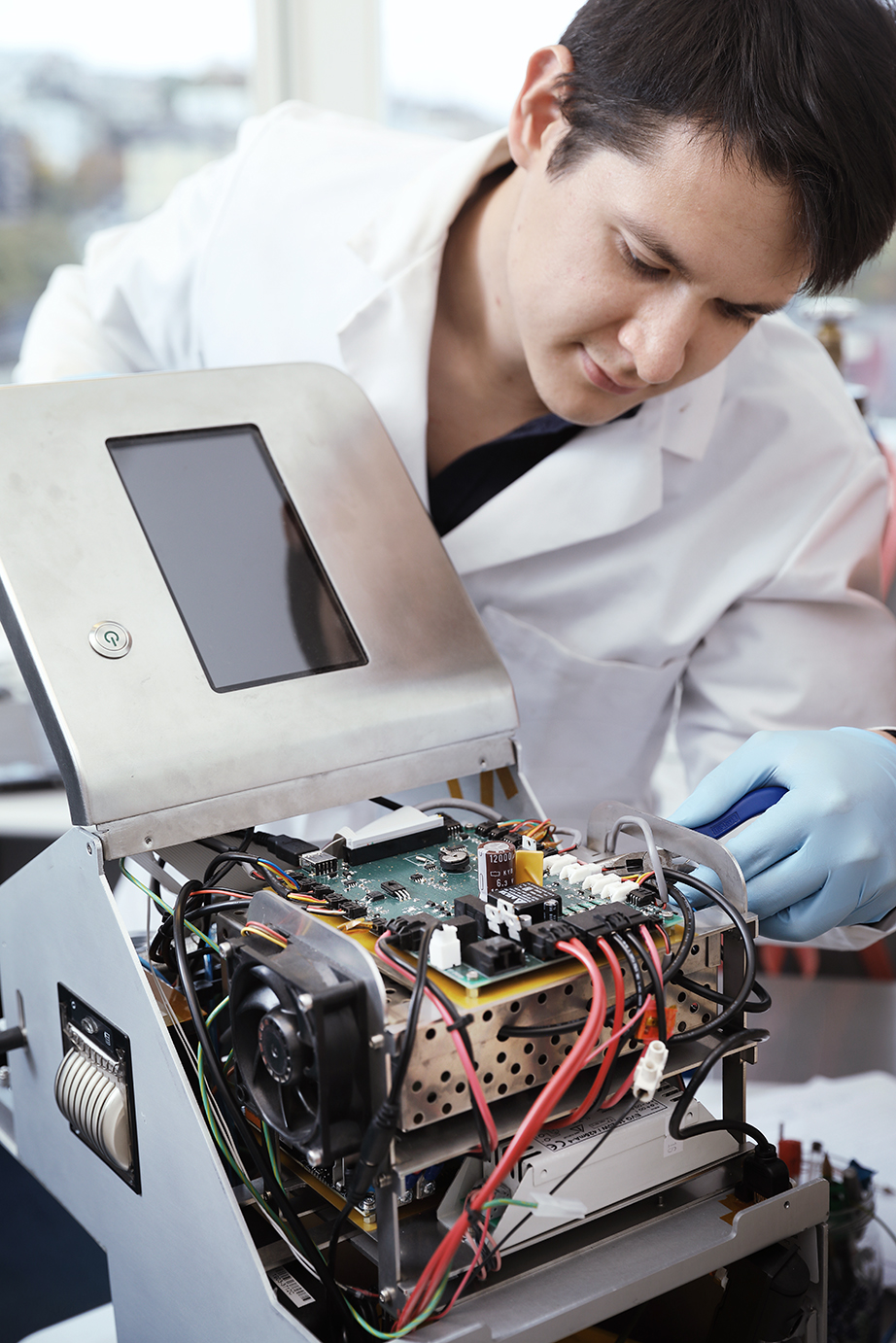

Our technical team aims to ensure the quality of the equipment and is committed to the assistance of our customers

Frequently asked questions

The SterOx System was developed to sterilize instruments that are moisture or heat sensitive (i.e. not compatible with steam sterilization).

Instruments that are compatible with the SterOx System include:

| Batteries | Electrocautery pens | Laparoscopic forceps |

| Laparoscopy trocar | Endoscopic accessories | Dopplers |

| Shaver handpieces | Resectoscopes and working elements | Cryoprobes |

| Surgical Drills | Fiberoptic light cables | Laser handpieces |

| Laryngoscopes | Thermometers | Defibrillator Paddles |

| Video cameras and couplers | Ultrasound probes | Skin staplers |

| Otoscope | Dermatoscope | Stethoscope |

And many more…

The SterOx System has been tested with Geobacillus stearothermophilus spores, which is the most resistant microorganism to the ozone sterilization process. More information is available under the menu Technology.

The SterOx System has obtained the European conformity (CE mark) which means that it meets essential requirements and complies with all applicable EU directives.

Throughout the whole duration of the cycle, the SteriBase precisely measures and monitors the ozone concentration inside the SteriBox. At the end of the cycle, if the total ozone dose is above a specific threshold then the SteriBase will print out a sticker indicating that the cycle was completed. If not, then it will print out a sticker mentioning that the cycle failed with an error code. Error codes are listed in the instructions for use manual with troubleshooting steps.

HUMIDIFY – Blotting paper

5 mL of water are required for successful sterilization. These 5 mL of water are added on a blotting paper that has been designed to regulate the relative humidity in the SteriBox.

OZONE STRIP – type 1 chemical indicator

This indicator is meant for use with individual items, for example sterilization pouch, to indicate that a unit has been exposed to ozone and differentiate between processed and non-processed units.

OZONE STRIP – type 4 chemical indicator

This indicator is a multi-variable indicator that reacts to all critical variables in the sterilization cycle (i.e ozone concentration, humidity level, time of exposure). This indicator can be used as an additional monitoring tool to release loads that have been sterilized.

Nitrogen gas supply

To function properly, the SteriBase requires a nitrogen gas supply. SteriLux SA distributes a compact disposable nitrogen cylinder (40 cycles capacity) for customers that have little space available. However, if enough space is available, it is possible to purchase reusable commercially available nitrogen supply cylinders.

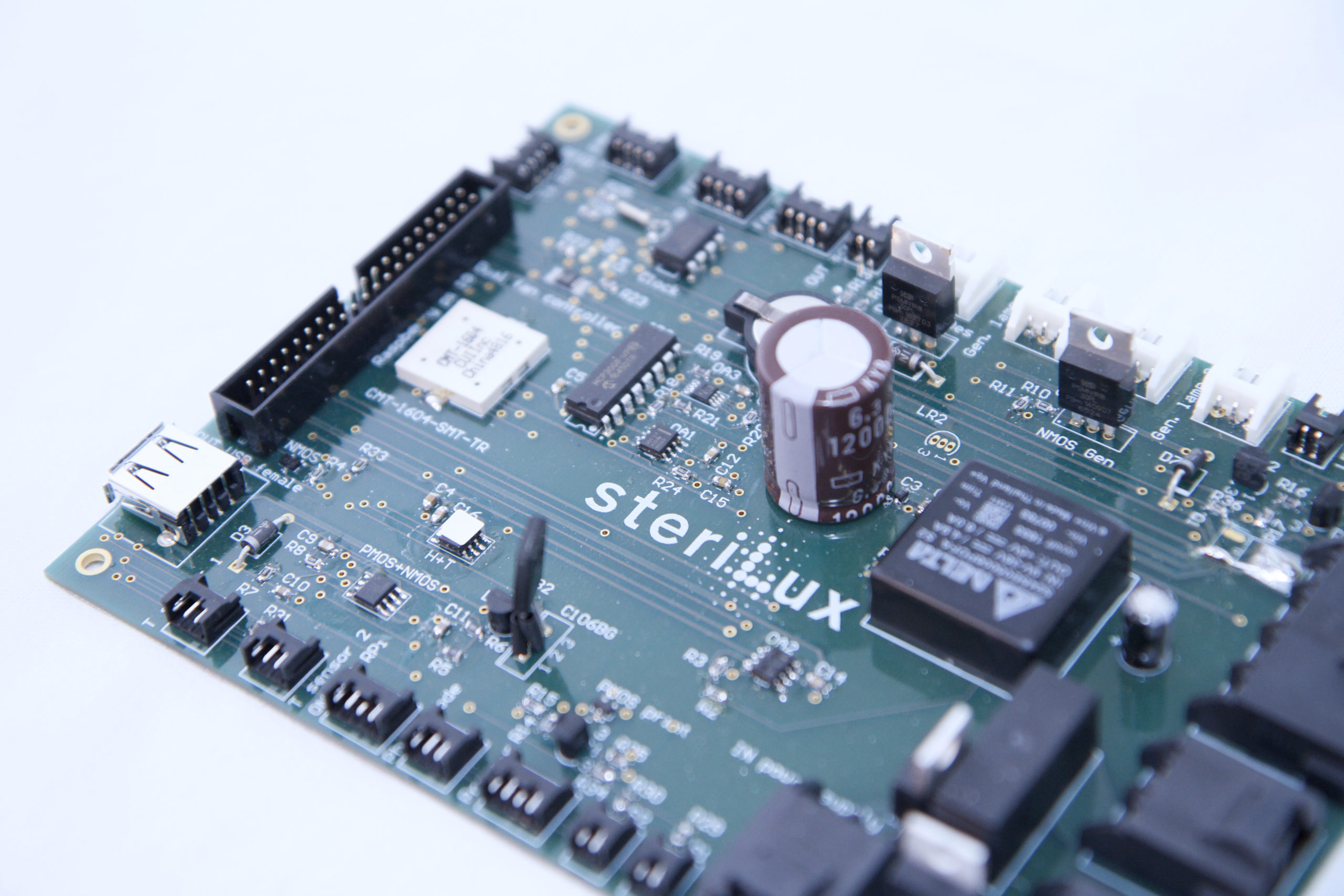

Nitrogen is not directly involved in the sterilization process, however it is essential to have good ozone generation inside the SteriBox and avoid failed cycles. Nitrogen is used to fill up the most important unit situated inside the SteriBase that contains the UV lamps (i.e. the lamp unit). If there is no nitrogen supply, the lamp unit will be filled up with oxygen which will prevent a good generation of ozone inside the SteriBox and thus increase the probability of having failed cycles.

During the first 10 minutes of every cycle a nitrogen purging of the lamp unit will occur using approximately 6 litres of nitrogen.

Note that the disposable nitrogen cylinder provided by SteriLux is 1.34 litres at 110 bar which amount to a total volume of 147 litres 1.34×110). Therefore with one nitrogen cylinder up to 20 cycles can be performed.

Each sterilization cycle requires a blotting paper. However, the chemical indicators are always optional.

Adding 5 mL of water is essential to ensure successful sterilization. Ozone reacts with water molecules to form free radicals which are highly reactive species that will kill all microorganisms (bacteria, yeast, fungi, viruses, spores).

Yes instruments can be individually wrapped in commercially available sterilization pouch. We recommend the use of Tyvek®-plastic pouch which have been cleared for use in the SterOx System.

The SteriBox has an internal volume capacity of about 20L. The entire volume is usable.

Instruments to be sterilized must be free from all residual matter, such as blood or organic tissue. Instruments must also be dry and free from mineral deposits. Such substances may cause damage to the instruments or impede the sterilization process.

Always check that the quartz window on the SteriBox is clean and that the inside of the SteriBox is dry prior to launching a cycle.

Do not place cellulose or cotton-based material as this will absorb ozone and prevent effective sterilization.

The delivery time is 3 months.

The device is low maintenance. Most of it can be done remotely when the device is connected to a stable Wi-Fi connexion, including but not limited to software updates.

It is recommended to perform a preventive maintenance once a year to optimize the device lifetime. This is not mandatory.

In case of defect, SteriLux repatriates the device and loans a replacement device for the duration of the repair.

For a period of 2 years, SteriLux guarantees that the SterOx System, when manufactured by SteriLux in new and unused condition, will not fail during normal service due to defects in material and workmanship that are not due to apparent abuse, misuse, or accident.

The two-year warranty covers the performance of all components of the device, provided that the product is being used and maintained according to the description in the user’s manual.

Ozone is a blueish gas with a very pungent characteristic odor. The odor threshold for humans is from 0.003 to 0.010 ppm. It is detected at a concentration significantly lower than the exposure limit.

Ozone can irritate the respiratory system and cause health issues above a certain threshold. However, in the SterOx System, the user is never exposed to dangerous ozone doses as ozone is actively reverted back to oxygen at the end of the process.

Instructions for use

Here you can download the official training material to familiarize yourself with the SterOx System.