The sustainable low-temperature ozone sterilization solution

scrollEco-friendly

Waste- and chemical-free process relying on limited energy resources. Ozone does not leave toxic fumes or residues; rather it converts back to oxygen that can be safely released into the environment.

Safe

Parameters are monitored to guarantee process efficiency and effective destruction of all microorganisms (bacteria, yeast, fungi, viruses and spores). The durable container allows extended sterile storage.

Cost-Effective

The low-maintenance process relies on the use of UV radiation to generate ozone from ambient air. Designed to operate with minimized costs per cycle, devices’ lifetime is preserved by a gentle process.

This innovative technology adapts to your needs

-

For medical practices

Our compact ozone sterilization device is suitable for any medical practice wanting to sterilize heat- and moisture-sensitive devices in-house at an affordable cost.

Discover -

For veterinary clinics

Our low-temperature sterilization process is a safe alternative to ethylene oxide to sterilize single-use devices (eg. LigaSure™, Caiman®, electrocautery pens…) and other heat-sensitive devices.

Discover -

For research labs

Our process is the most delicate sterilization process on the market. Performed at room temperature and atmospheric pressure, it is compatible with a wide range of applications.

Discover

A proprietary patented process

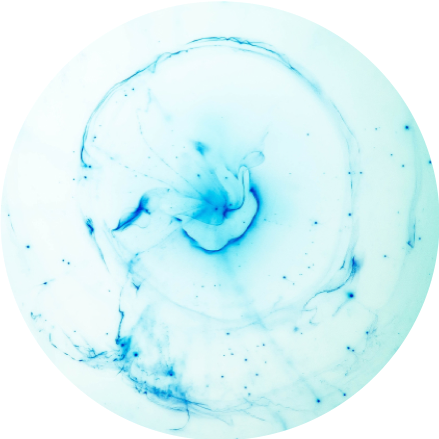

The process relies on the use of 172 nm V-UV lamps to transform oxygen from ambient air into ozone (O3), a naturally occurring biocide gas also known as trioxygen. Ozone further reacts with water molecules (H2O) to form hydroxyl radicals which are highly reactive species responsible for the inactivation of all microorganisms.

At the end of the sterilization process, a 254 nm V-UV lamp transforms the remaining ozone back into oxygen.

The process is compliant with applicable norms relative to the microbial effectiveness of the sterilization process.

(i.e. ISO 14937:2009, ISO 11138-7:2019)

About us

SteriLux is a Swiss MedTech start-up founded in August 2014 with the ambition to have a major impact on the improvement of quality medical care.

As a young company, we are committed to combine quality, technical expertise and innovation to transform the way infection control is addressed. SteriLux’ products are developed and manufactured under ISO 13485:2016 Medical Devices Quality Management System.

Next events see all

-

AFVAC

- Lille

- Nov 26, 2026

-

WSAVA World Congress

- Varsaw

- Oct 13, 2026

-

ESVOT

- Rome

- Sep 23, 2026

-

ECVIM-CA ANNUAL CONGRESS

- Berlin

- Sep 10, 2026

-

ESVC

- Liverpool

- Jul 9, 2026

-

BVA Live

- Birmingham

- Jun 11, 2026

-

EVECC CONGRESS

- Edinburgh

- Jun 4, 2026

-

Deutsche Vet

- Köln

- May 29, 2026

-

SCIVAC

- Rimini

- May 29, 2026

-

VMG Congress

- Stratford-Upon-Avon

- Apr 22, 2026